Last Saturday, our team served as the rescue and attendant crew for a confined space job permitted for welding only. Atmospheric monitoring was set up using a 4-gas meter calibrated to pentane for LEL, and early readings appeared safe.

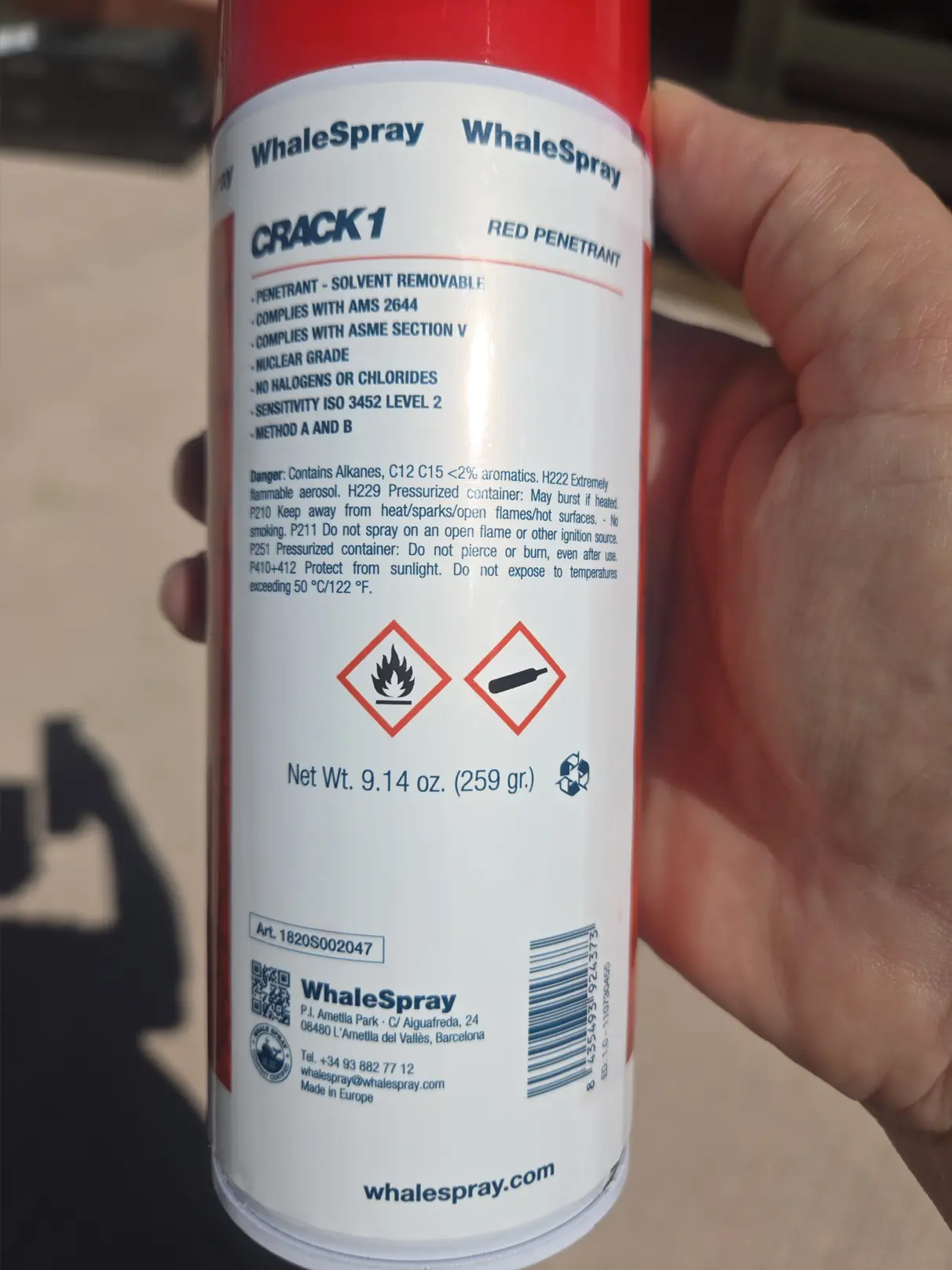

Mid-job, without any update to the permit, the scope shifted to weld inspection. The contractor introduced Crack 1/2 spray to prep the area—loaded with C12–C15 alkanes. No disclosure. No revalidation. No heads-up.

The entrant sprayed the product—and within seconds, the meter went into alarm. He evacuated immediately.

The 4-gas meter didn’t display VOC levels. Only later, using correction factor calculations, did we identify the true exposure:

- LEL: 50% (displayed)

- VOC: 120ppm (calculated using correction factor)

The entrant had briefly been inside a space with a confirmed explosive atmosphere, and the permit logic never flagged it.

Hard Lessons:

- Unreported scope change = unmitigated hazard

- Chemical introduction must trigger workflow gates

- Correction factors are essential—hidden risks won't show up on standard meters

- Alarms work—but they’re the last line of defense

This wasn’t theory—it was an actual breach. Safety logic must evolve to catch risks like this before they reach a crew inside.

📎 Download the crew-ready Toolbox Talk handout attached to this post for easy field distribution.