When we teach confined space safety, the 4-gas monitor is standard fare. But sometimes, real risk hides in what it doesn’t show. That was the case recently during a tank cleaning operation in a pharmaceutical facility—where a subtle ventilation misstep let VOC levels climb far beyond acceptable exposure thresholds, without triggering a single alarm.

What followed was a practical lesson in sensor awareness, airflow dynamics, and fast-acting field leadership—and it led to a 100 ppm drop in hazard levels in under 10 minutes.

🛠️ The Setup

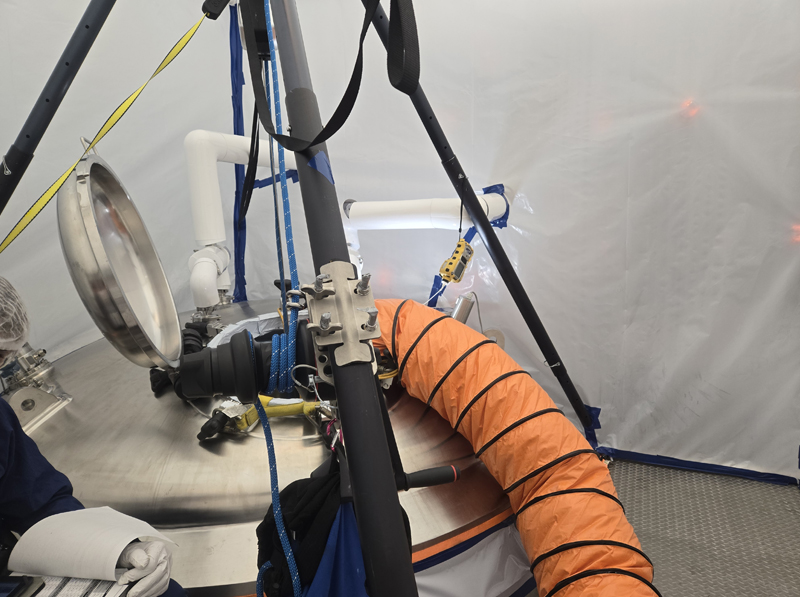

- Job: Internal tank cleaning

- Protection: HEPA tent enclosure and positive-pressure ventilation

- Monitoring: MultiRAE PID, VOC target: isopropylamine

- 4-gas readings: All clear

- VOC reading inside tank: 130 ppm

- VOC inside tent: 100 ppm

- No alarms. No flammability detection. Just high exposure risk.

🛡️ Respiratory Protection Confirmed

As part of the pre-job briefing, the team reviewed the Safety Data Sheet (SDS) for isopropylamine and recognized the potential for airborne concentrations to exceed both TWA and STEL thresholds during internal tank cleaning. Based on this hazard evaluation, the worker entering the confined space was equipped with appropriate respiratory protection, aligned with projected exposure levels and site safety protocol.

Thoughtful planning and proactive PPE selection were in place before entering the space—not after VOCs were detected.

🔎 The Realization

Despite a clean 4-gas, something wasn’t right—why were VOCs still high outside the tank? That’s when the crew stepped back and spotted the issue:

The positive pressure fan was drawing air from inside the tent instead of from a clean source outside.

They were unintentionally recirculating contaminated air, just moving it faster. A classic airflow short-circuit.

✅ The Fix

The team repositioned the fan intake to source air from outside the tent. The impact was immediate:

- VOC levels dropped from 100 ppm to 30 ppm inside the tank and below 5 ppm inside the tent

- No change in equipment—just smarter airflow

🧠 Why It Mattered

| Exposure Limit Type | Limit | Purpose |

|---|---|---|

| TWA (8-hour average) | 5 ppm | Long-term exposure safety |

| STEL (15-minute max) | 10 ppm | Short-term irritation prevention |

| IDLH | 750 ppm | Emergency action threshold |

At 130 ppm, the tank atmosphere was 26× above the TWA and 13× above the STEL. The 4-gas monitor didn’t sound the alarm—but the PID, and most importantly, the crew’s awareness, did.

🔥 What We Learned

- A HEPA tent can contain hazards just as easily as it contains workers

- Ventilation placement matters as much as ventilation presence

- PID sensors cover what the 4-gas monitor can’t see

- Real-time air sampling = real-time protection

- Good air isn’t lucky—it’s built

🚀 What We’re Doing Next

This case is now part of our:

- 🧾 Training curriculum

- 📱 App-based field guide (in development)

- 🎓 Handout for confined space and VOC response teaching

- 📢 Messaging: “Not everything is in the 4-gas.”

Because when exposure slips through the cracks of standard monitoring, it's expertise, teamwork, and real-time observation that close the gap.

Want the downloadable training handout? Contact us—or check the Hux Field Ops app update coming soon.